Description

FoamWorks

FoamWorks is a handy tool that makes it super easy to create instruction sets for foam-cutting CNC machines. You might think technology has only changed computers, but now there are all sorts of devices that can print objects in 3D!

Getting Started with FoamWorks

Installing FoamWorks doesn’t take long at all. Just a heads-up: you’ll need the .NET Framework on your computer first. If you don't have it, it’s best to check that before diving in! The cool part? You don’t actually need a CNC machine right away. FoamWorks just builds the instructions you can use with your regular machine communication tools.

No Design Elements Included

Keep in mind that FoamWorks doesn’t come with any design features itself. Instead, it creates code files from existing designs. It supports popular CAD DXF files, but make sure to set them up in pairs of different layers so you can figure out how deep to cut.

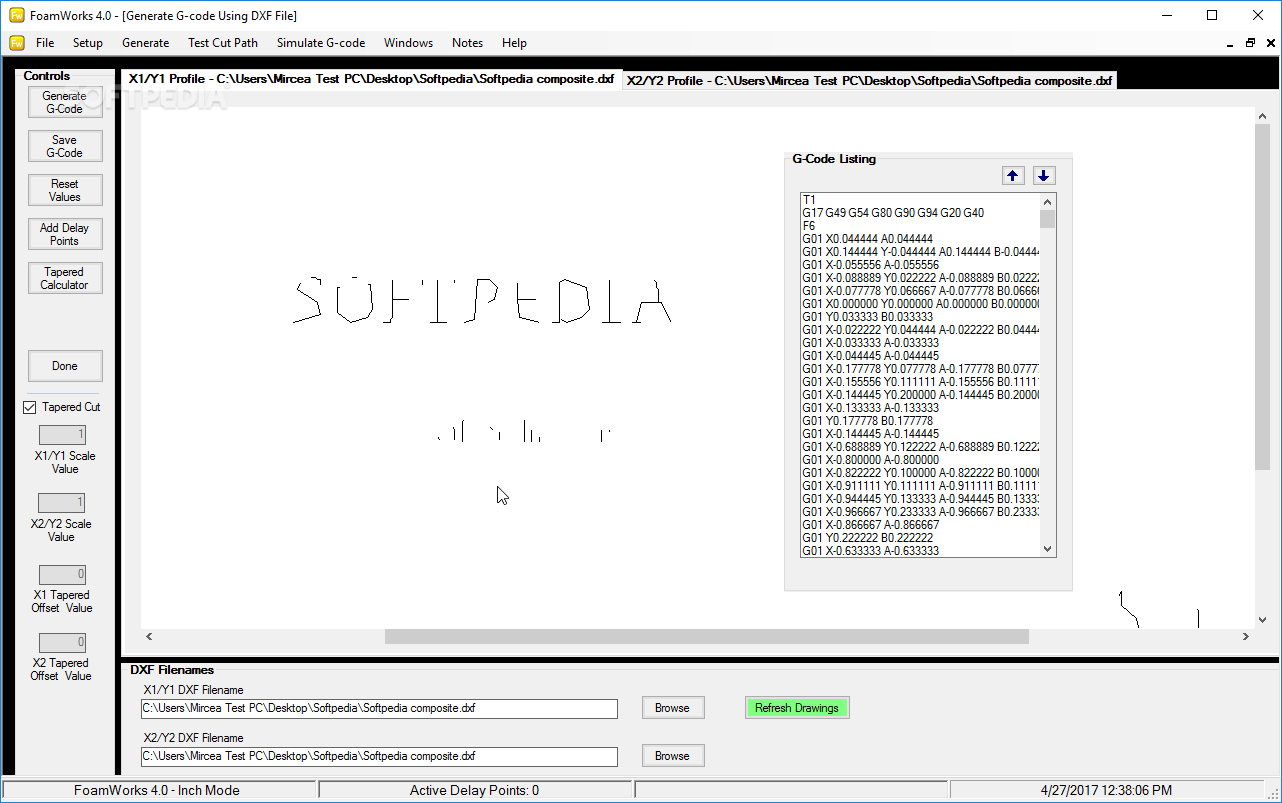

Preview Your Designs

Once you load your DXF file, FoamWorks generates a preview right on the screen! You can zoom in and pan around to get a better look at your design. When you're ready, just hit the button and voila—the code is generated! You’ll see all your instructions lined up in a handy floating panel.

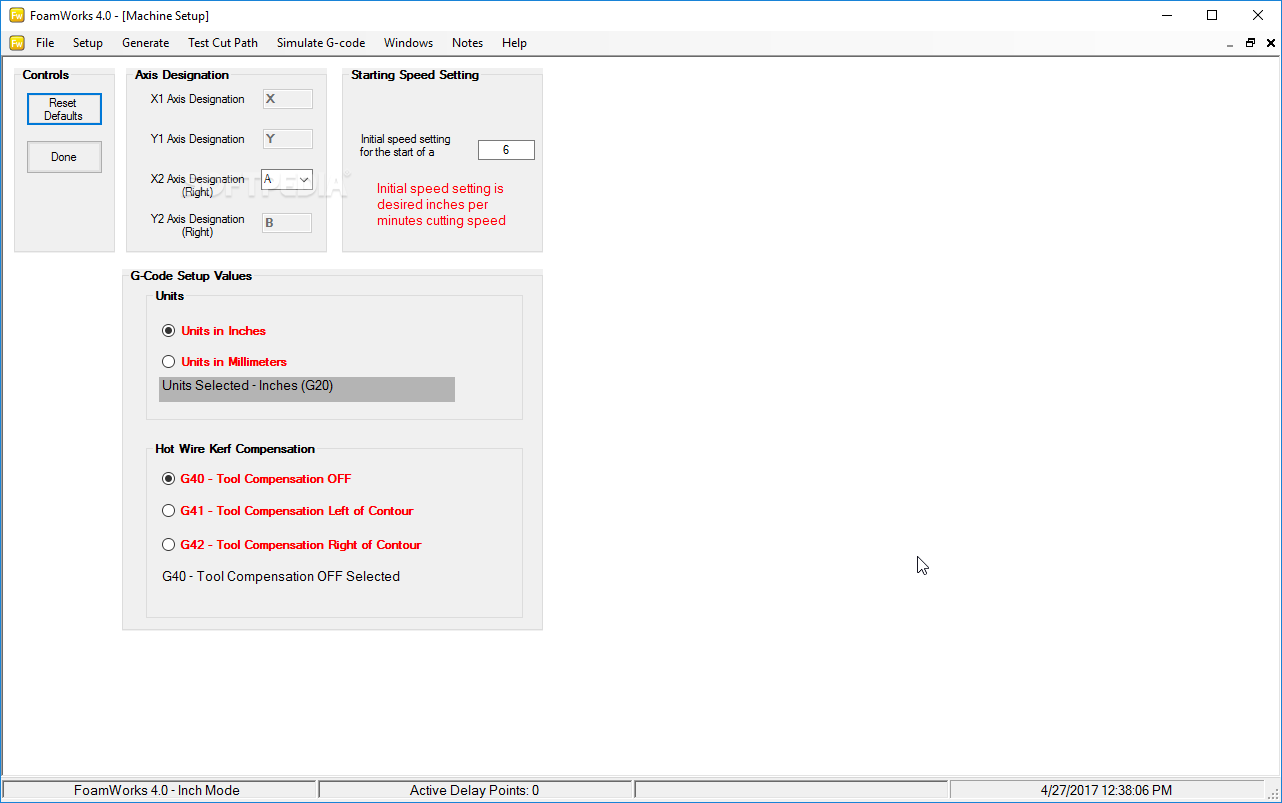

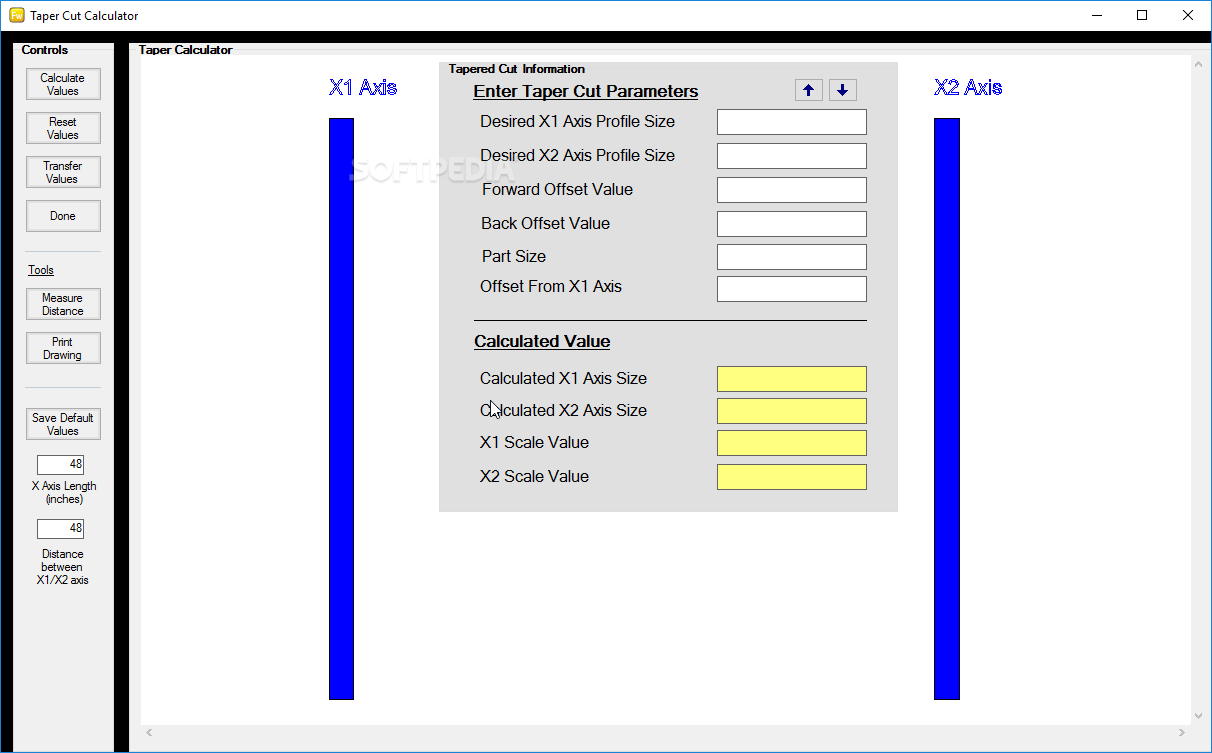

Choose Your Cut Type

You can create code for regular cuts or tapered cuts. If you go with tapered cuts, there's even a calculator built-in to help figure out X1 and X2 axis sizes and scales. Plus, you can tweak other project settings like initial speed and G-code setup values based on the measuring units you're using.

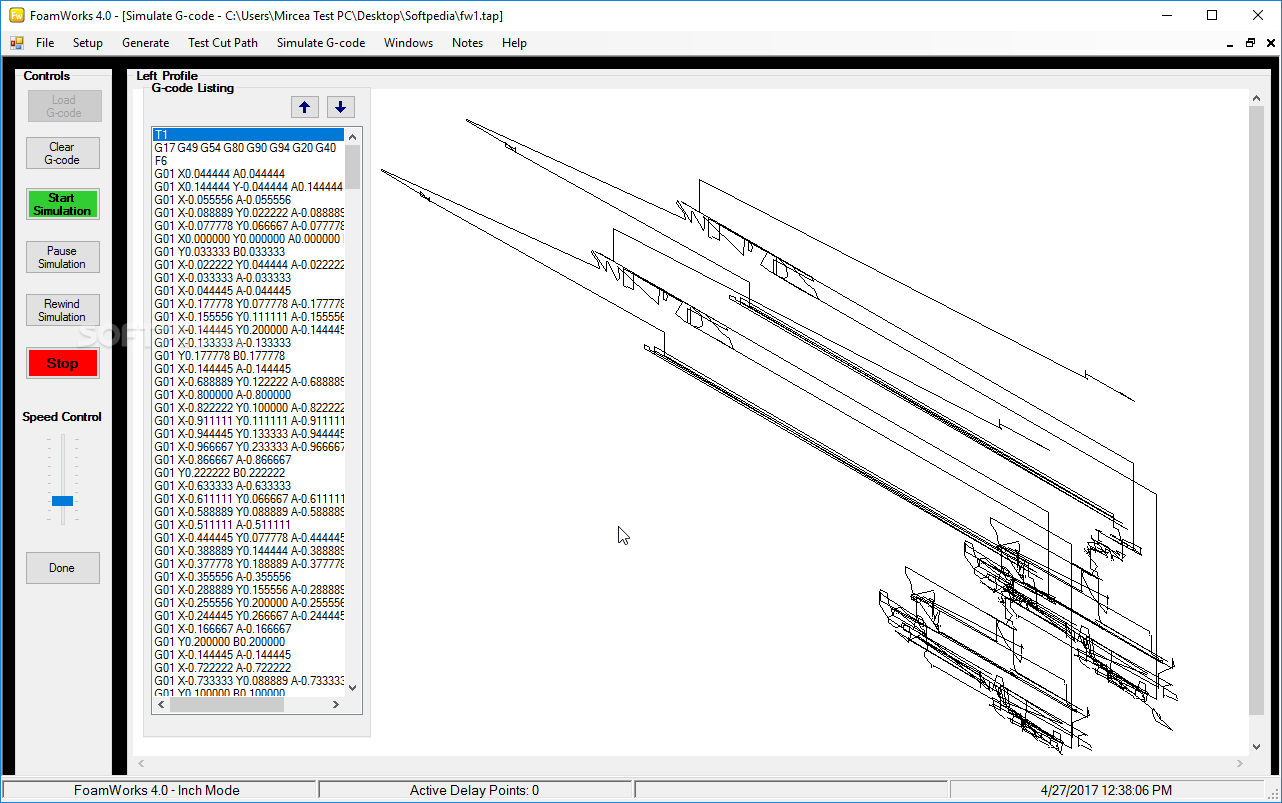

Simulate Before Cutting

The built-in simulator is a great feature too! It lets you analyze your project before cutting—no need for an actual DXF file here; just use the G-code file instead. You can adjust how fast the simulation runs while watching each step of your design come together.

Generating G-Code Files

If you only want to generate G-code without running a full simulation, that's totally possible with DXF files too! Just remember, while FoamWorks can't directly link to your CNC machine, the resulting G-code files work perfectly with popular CNC control programs like Mach3.

The Future of 3D Printing

To wrap things up, 3D printing machines are becoming more common these days. Programs like FoamWorks handle all those complex calculations for us! Importing CAD designs is easy for assembling code and simulating cuts—making life so much simpler!

User Reviews for FoamWorks 7

-

for FoamWorks

FoamWorks simplifies foam-cutting instructions for CNC machines. Easy to use, supports DXF files, and includes simulation feature for final analysis.

-

for FoamWorks

FoamWorks is a game-changer for foam cutting! Easy to use, it creates accurate G-code from DXF files.

-

for FoamWorks

I love how FoamWorks simplifies the process of generating instructions for foam cutting machines!

-

for FoamWorks

Fantastic app! It efficiently generates G-code and the built-in simulator is super helpful for testing.

-

for FoamWorks

FoamWorks makes foam cutting projects so much easier. The interface is user-friendly and intuitive.

-

for FoamWorks

Highly recommend FoamWorks! It supports DXF files well and produces precise cutting instructions seamlessly.

-

for FoamWorks

Excellent tool for anyone working with foam. The simulation feature is a great addition for quality checks!